The Liquid Controls MASTERLOADx.iQ is a microprocessor-based electronic meter register that can be used for Weights & Measures approved custody transfer actions in mobile or fixed installations.

NOTE: Throughout this manual, the MASTERLOADx.iQ is referred to as “Register” (unless otherwise specifically referenced by name). |

The Register is a self-contained unit. All operation, setup, and configuration functions can be carried out using the Register function keys and alphanumeric keypad. No lap pads, laptops, or other data entry devices are required.

A complete Liquid Controls meter system not only accurately measures product, it also regulates product flow and removes contaminants in order to produce the optimal conditions for measurement. Typical systems include an air/vapor eliminator, strainer, meter, register, and control valve.

It's just that simple.

Liquid Controls engineers took an aggressive approach by designing the Register from the operator's perspective, as if little training should be required to use it. The result is a user-guided, configurable interface that walks the operator through the fueling operation, minimizing chance for error.

COMMON FUELING PROCESSES COMPLETED IN 3 STEPS OR LESS

User-configurable fueling processes control the number of steps required for the operator to complete his or her delivery. Pump and print operations are complete in two steps, using one function key.

OPERATOR FRIENDLY SCREENS WITH DAY / NIGHT MODES AND BRIGHTNESS CONTROL

The Register screens adapt to the operator. Idle screen shows the last delivery data, changing to full screen, active fueling mode with yellow background when Start is pressed. Operators have the option to see fueling details during active fueling and can easily adjust screen brightness and toggle between day or night modes for reduced eye strain.

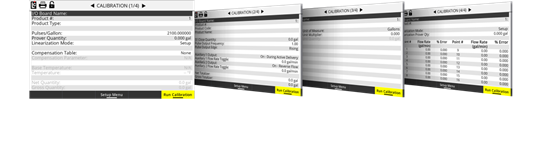

SIMPLE METER CALIBRATION

The intuitive calibration of the Register enables you to simply enter the "corrected prover" or master meter volume, and it will do the rest. With up to 16 points of linearization, the Register is by far the most precise register ever made.

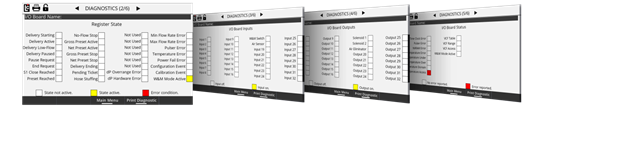

REAL-TIME ON-SCREEN DIAGNOSTICS

The Register provides the operator with real-time diagnostics. It also provides an error indicator and message for any error condition that arises. Also, the operator can easily print the report for corrective action and reference.

SECURITY

The Register has been designed with the highest levels of securit,y according to Center for Internet Security (CIS) benchmarks. As an Internet-enabled device, it is imperative that any weights-and-measures-approved devices meet or exceed CIS benchmarks for security. This level of stringency also provides a robust user level security to prevent tampering or inadvertent access to forbidden areas and settings on the device. Safety and security go hand-in-hand, and these are the number one priority at Liquid Controls.

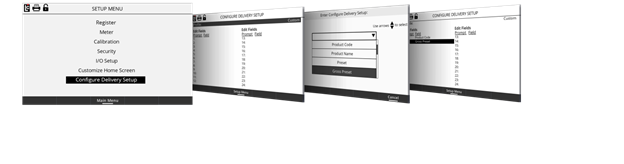

CONFIGURABLE DELIVERY SETUP

Guide the operator through the fueling process of your choosing. From basic pump-and-print to presetting–either by volume or product weight. It's easy to adjust price per gallon, percent tax, or select multiple deliveries on a single ticket.

CONFIGURABLE IDLE SCREEN

Easily configure the idle screen fields the operator sees before, during, and after fueling. All units of measure including date and time formats are also configurable to comply with local standards.