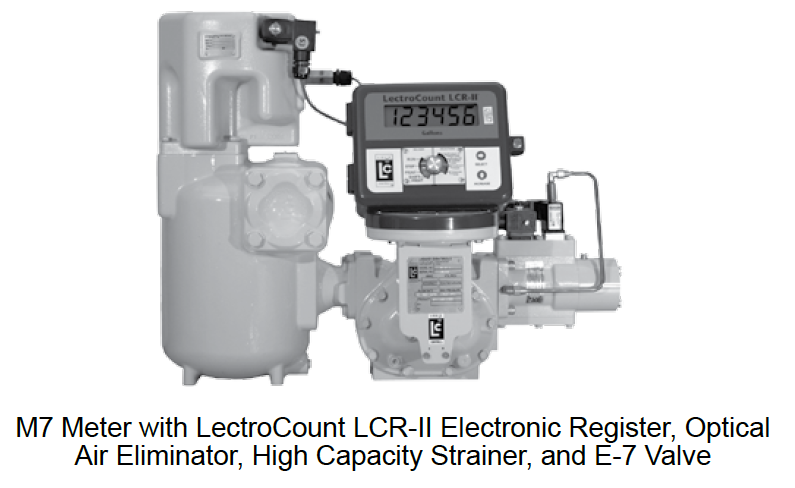

Meter System Components

METER SYSTEM

A Liquid Controls meter system not only accurately measures product, it also regulbates and purifies product flow in order to produce the optimal conditions for measurement. Optimal systems typically include an air/ vapor eliminator, strainer, meter, register, and control valve. The LectroCount LCR-II, a register, serves as the central controller of the meter system. Most components in the meter system are hard wired to the LCR-II via data communication cables. See manual M100-10.

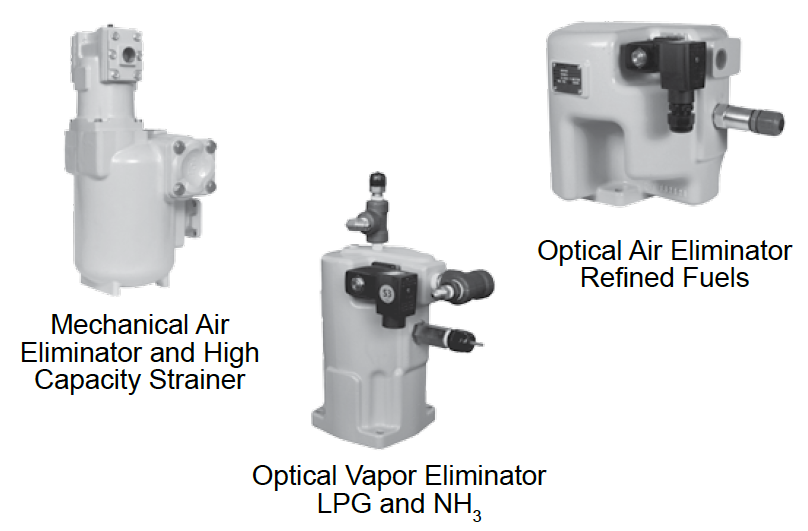

AIR / VAPOR ELIMINATORS

Air and vapor eliminators sense and remove air or vapor in the piping before it enters the metering system, ensuring that only liquid will pass through the meter for measurement. Mechanical air eliminators do not require a data connection to the LectroCount LCR-II (in LPG applications, they are often plumbed to a 3-way solenoid which is wired to the LectroCount LCR-II). Optical air eliminators use an optical sensor to monitor liquid levels and a solenoid-actuated valve to turn the vapor vent on and off. The optical sensor and the solenoid valve are connected to the LectroCount LCR-II by separate data cables. See manuals M300-20 and M300-21.

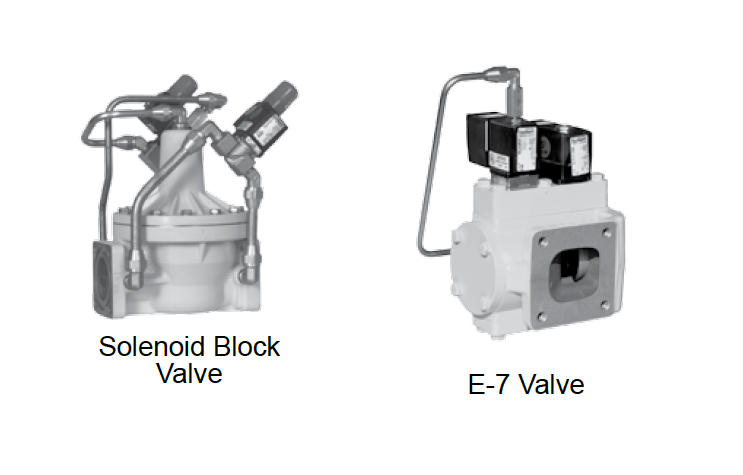

VALVES

Valves control the flow through a metering system. They open the line to initiate custody transfers and close the line to stop custody transfers. Some valves can partially close, slowing the flow rate to a dwell flow on preset deliveries. By slowing the flow rate, valves can lessen the hydraulic shock incurred by the meter system upon shut off and provide accurate preset deliveries. Many valves use solenoid-operated valves that require a hard-wired data connection to the LectroCount LCR-II. See manuals M400-11 and M400-40.

ELECTRONIC TEMPERATURE VOLUME COMPENSATION (ETVC) KIT

In order to perform temperature compensation equations, the LectroCount LCR-II relies on a temperature probe inserted into the strainer housing. Installation directions for the ETVC kit are included in this manual.

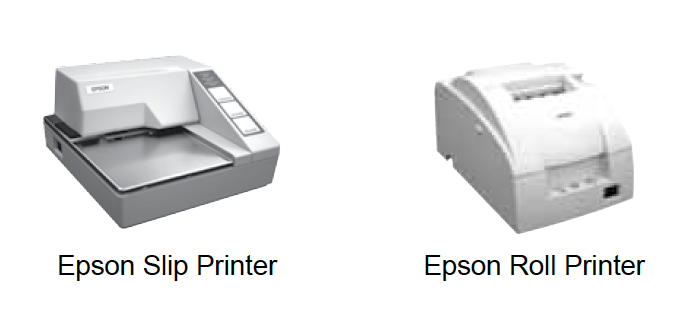

PRINTERS

Printers print delivery tickets to provide a physical record of custody transfers. The Epson slip printer is considered the industry standard for many applications. Multilayered tickets are available to provide a physical record for both customers and business records. The Epson roll printer is ideal for recording multiple custody transfers over an extended time frame.

LECTROCOUNT REMOTE DISPLAY

The 2¼" digits on the Liquid Controls LectroCount Remote Display allow operators to view the register totalizer values from distances of up to 100 feet. Hard wire data communication with the LectroCount LCR-II is required. See manual EM100-13.

PULSE OUTPUT DEVICE

The Liquid Controls Pulse Output Device (POD pulser) converts the rotary motion of a positive displacement flowmeter into electronic pulses. POD pulsers can be used in place of an internal pulser. They are ideal for applications that require explosion proof components in which the LectroCount LCR-II register is installed at a distance from the meter. The POD pulser requires hard-wired data communication with the LectroCount LCR-II. See manual EM300-11.

DIFFERENTIAL PRESSURE (ΔP) TRANSDUCER

The differential pressure transducer, common in aviation applications, monitors the differential pressure (pressure drop) across a full flow fuel monitor/water coalescer. The highest differential pressure reached during the custody transfer will then be printed on the ticket. Using interlocks, the LectroCount LCR-II can shut down a custody transfer if the differential pressure meets a preprogrammed differential pressure shutdown value. The ΔP Transducer requires hard wired data communication with the LectroCount LCR-II. See manual EM300-40.

DATA MANAGEMENT SYSTEMS

The DMS i1000 is an in-cab computer with a heavy duty lap pad interface. The DMS i1000 streamlines the flow of data between the LCR-II and back office accounting software. The DMS i1000 must be hard wired to the LectroCount LCR-II. See manuals EM200-10 and EM200-11.

LAP PAD

The lap pad programs and displays all operational functions of the LectroCount LCR registers. It has a large, tactile, alpha-numeric keyboard and a dual line, backlit display. A 3-terminal lap pad adapter is provided with each lap pad. The adapter provides a junction for the lap pad, the printer, and the LCR printer cable.