IMPORTANT: Before Sealing the Register |

After correctly powering up the Register, continue on to the Register Setup and Operation manual to setup the Register for operation. We recommend that you setup and test the Register before closing and sealing the unit. |

Close and Seal the Unit

After setting up and testing the unit, complete the installation by closing and sealing the housing. The Register must be environmentally sealed to protect the electronics against the elements. The Register must also be sealed by a Weights & Measures representative to guarantee that the register is operating at the proper regulatory standards.

1.Secure the cables behind the Register and the cables in the cab with cable ties.

2.If conduit was used during the installation, fill the conduit end inside the Register with silicon RTV (provided with shipment, PN 82575). Read and follow the directions of the Environmental Sealing Guidelines, below.

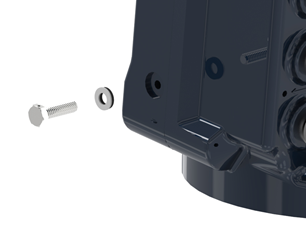

3.Tighten the four socket head cap screws on the four corners of the cover housing using a 3/16 hex key or bit. Ensure that the gap between the cover and the housing is completely closed. Ensure that the calibration screw is tightened to approximately 7-lb–and properly sealed. Read and follow the directions of the Environmental Sealing Guidelines, below.

4.Seal the cover, base, and calibration screw with a wire/lead seal. See the Weights & Measures Seals section below.

Environmental Sealing Guidelines

The Register includes sensitive electronic components, including a microprocessor that can be damaged by the presence of moisture. Therefore, it is essential that all conduit ports, the cover, and the shaft seals be adequately sealed by the installer to ensure watertight integrity. The conformal coating on the board mitigates the problem of corrosion due to moisture, but this measure only protects the board from small amounts of moisture trapped inside when the lid is closed in humid conditions. It is not adequate for protecting the unit over time if a continuous leak is present in the enclosure.

Sealing the Register is the Responsibility of the Installer |

There is no product warranty coverage for any water or moisture damage to the Register that results from improper sealing. |

1. Conduit Entrances

The Register housing has 11 conduit entrances, all are ½" NPT female threads. Use only ½" NPT male threaded fittings on the conduit entrances. Thread sealant must be used with NPT threads. Pressed-in Caplugs or straight (rather than tapered) threads are inadequate for sealing these entrances. Acceptable fittings include metal or plastic conduit, pipe plugs, or cable glands.

Apply PTFE-based “pipe dope” to threads, or wind a minimum of two revolutions of PTFE tape prior to installation. Engage the threads with a minimum of four full turns.When using cable glands, ensure that the gland is sized properly for the outside diameter of the cable and the elastometric seal around the cable sheath is compressed onto the cable. Use only one cable per cable gland, unless the gland accommodates for multiple cables. When using conduit or Liquid-Tite, ensure that the opposite end is connected to an environmentally sealed device. If the conduit is not sealed at the other device, fill the interior of the conduit at the Register with a silicone rubber sealant–such as RTV–to prevent moisture from running down the conduit into the enclosure.

2. Cover Seals

To seal the Register cover properly, ensure that the O-ring surrounding the cover is fit snug inside the groove, and securely tighten the cover screws.

3. Shaft Seals

Units with internal pulsers have an O-ring around under the pulser inside the enclosure, and also a pulse encoder drive shaft that extends through the bottom of the Register housing. If a drive shaft adapter was attached at installation, ensure the O-ring around the shaft is securely seated in the counter bore of the casting, covered with the flat washer provided, and held in place with the cotter pin provided.

Any water or moisture damage to the Register as result of improper sealing will not be covered under the product warranty. Sealing the Register is the responsibility of the installer.

Weights & Measures Seals

To detect possible intrusions into Weights & Measures approved calibrations on a Register, retainer holes have been drilled into the side of the enclosure adjacent to the Weights & Measures Screw. Properly tighten the Weights and Measures screw to approximated 7 lb-in of torque or the proper visual tightening.

To seal according to Weights & Measures standards, a wire is threaded through the retainer holes and closed with a lead seal.